Everlast Cyclone 212

Welcome to Fab Supply & Co, your go-to source for high-quality welding consumables and New Zealand’s exclusive Everlast Welders distributor.

MORE STOCK DUE START OF MAY

The ruggedly built Cyclone 212 performs like a bigger welder than it really is thanks to the powerful, yet space-saving design that is provided by the modern digital IGBT inverter construction. As both a MIG welder and a Stick welder, the Cyclone 212 takes advantage of every inch of its new space-saving design by providing up to 230A of MIG output while offering the capability to weld with either 8" (10-12 lb.) or 4" (2 lb.) spools of wire. And when you need it for those special stick projects, it offers a solid 160A output at 35% duty cycle which can handle most 5/32" 70XX welding rods.

The small package and the sleek new styling does conceal the capability of this welder quite well. The space minded case dimensions and generously sized carrying front/rear and middle choices for handles, it becomes apparent that this unit is designed for portability. The output ratings for both MIG and Stick combined with the dual 120/240V operating capability makes it a perfect go-to chore-hound for jobs in the shop and out on the job site.

Even though the Cyclone 212 is putting the industry into a ''whirl wind" with power, size and performance, we haven't stopped there with its design. In fact, we wanted to make this a truly groundbreaking MIG design that is positioned at the top of the industry for performance and features, without adding a huge price tag. We've done this by simplifying internals with a fully digital design inside and out. The space savings of a digitally controlled welder is significant by reducing the sum total amount of circuitry required. While it is often mistakenly thought that "digital" technology complicates things and makes repairs more difficult. To the contrary, it actually simplifies things by reducing the number of discreet components and allows the use of a "modular" platform where service components are largely plug and play in design. Less components, and solid-state parts means that there is less to go wrong, it is easier to diagnose, and it will typically provide a longer service life.

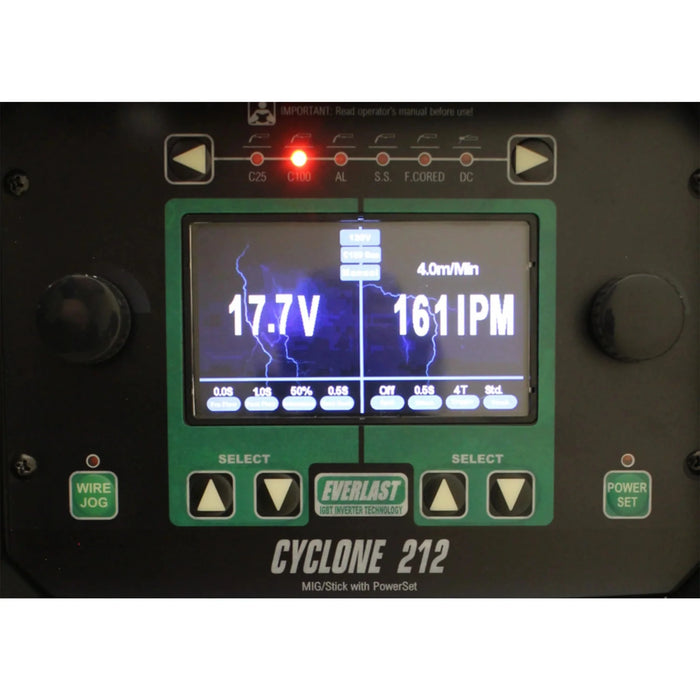

The new digitally controlled display panel of the Cyclone 212 is intuitively designed with both polarity reminders and a new PowerSet Function making setup simpler than ever. Whenever you plug the unit in, it begins to analyze the input voltage and automatically set and adjust the machine's output capabilities, and displays a input voltage reminder to you should you forget what power level you are operating on. Additionally, when you select a function, the machine also gives you an animated depiction and reminder of which polarity you should be operating on. This is important when switching between welding operations such as MIG to Flux-Cored welding, or vice versa where polarity does change and are critical to the correct performance of the welder. The Power Set function also allows the new and professional user to operate with authority, without having to look up or second guess setting choices. The design of the unit takes the user's input of wire thickness, metal type and plate thickness to offer the user an excellent starting point for parameters. Of course, no one setting will work for everyone, in every position, but the adjustability built into the PowerSet mode allows the user to dial-in the settings up or down to suit the demands of job. Of course, the unit performs well in the hands of the trained user in the standard mode as well, where everything can be adjusted normally.

The Cyclone also features settings like spot weld time, inductance, and burn back that allow the user to customize the unit to fit his/her own needs while in manual mode. In synergic mode, these settings are preset for the user so that they don't have to worry about the details if they don't want to. Of course, don't forget, the PowerSet mode works similarly for Stick as well and helps the user to match the best electrode up to the best power range for the smoothest running welds.

With 230A max output, the Cyclone 212 is aimed squarely at the 200A class MIG market by providing a solid 35% duty cycle at 200A. When the Amp output, duty cycle and overall size are examined, you'll find that this unit is right up there with the leaders and in most cases well ahead of many popular models. But what really pulls it clearly ahead of the leaders is the intuitive digital display and the ease of setup. The large color display is easy to see and stands out in brighter light conditions. With clear and intuitive function control, and the exclusive PowerSet function, setup takes mere seconds after switching the unit on.

If you wish to wire weld aluminum (between 1/8" and 1/4" thick), the unit can be used with our optional SM200N-MTS spool gun. However, for those with a tight budget, or don't need to be able to weld a long distance from the welder, the Cyclone 212 can be used with our polymer liner and U groove drive rolls using the standard MIG gun. That's right, for those on a budget, or who need to feed larger rolls of wire, no spool gun needed to weld Aluminum in MIG mode. Just change the liner and the drive rolls and you have instant welding capability without the added investment of a MIG Spool gun. Now, of course the optional MIG Spool gun works well with the unit too if you have the need and budget for it.

After you compare the Cyclone 212 features, performance and price to what else is out there in the marketplace, you are not going to find much that meets or beats the standards that this unit sets. This actually means that the Cyclone 212 has raised the bar and created a whole new class of MIG welders.

Features & Benefits:

- 230A MIG output, 160A Stick Output

- 600 IPM Wire feed speed 240V

- 400 IPM Wire feed speed 120V

- 4.3" TFT Digital Color Display

- New advanced version of PowerSet (Synergic) Function for MIG and Stick

- Dual Voltage 120/240V

- Digital IGBT Inverter design offers stable, low spatter arc performance

- Arc force control (Inductance) adjusts arc characteristics in both MIG and Stick modes

- Spot Timer

- Inductance for MIG

- Hot Start and Arc Force Control for Stick

- Burn Back Control

- 24 series MIG Gun with 10 ft. (3m) cable designed with comfort in mind (Binzel/Trafimet compatible)

- Eurostyle quick coupler allows easy aftermarket changeover to other MIG Guns

- Weld aluminum with optional Spool Gun or with MIG Gun with optional Polymer Liner and U-Groove Drive Rolls

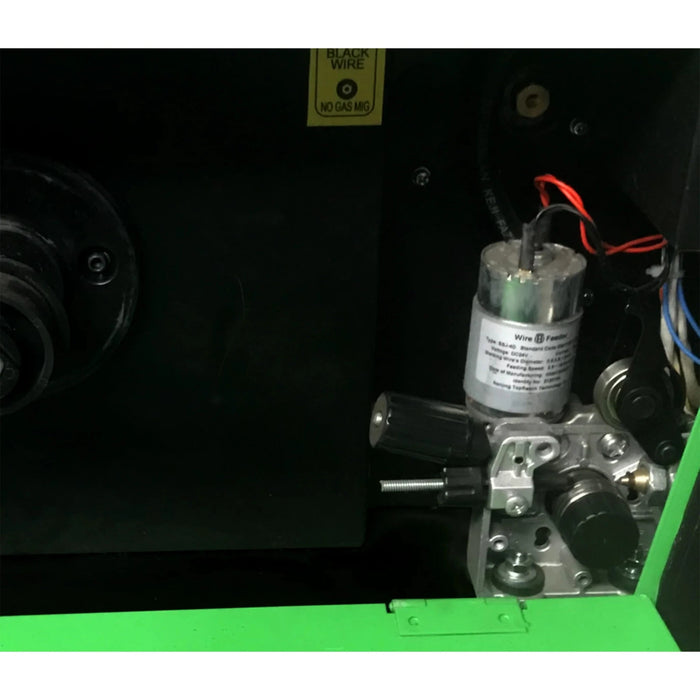

- Heavy Duty cast aluminum wire feed assembly with positive gear driven rollers

- Over current and duty cycle features both warning message and weld interrupt

- Polarity Reminder

- Pre and Post Flow Control

- Adjustable Burn back control

- Truly portable "suitcase" size and light weight

- .030-.035" V-Groove and Serrated groove (Flux-Cored) Stock drive roll size

What's Included:

- 24 series MIG Gun with 10 ft. cable and Euro style quick connector

- Stick Electrode Holder with 10 ft. cable and 35 DINSE connector

- Ground Clamp with 10 ft. cable and 35 DINSE connector

- AR/CO2 Regulator with Hose

- Drive Roll V Groove .030"-.035" (Single)

Specifications:

- Type: Digital/Micro-controlled IGBT Inverter

- Output /Process Type: MIG, Stick

- Voltage/phase: 220V 1 PHASE

- Max Rated MIG Amps: @ 220V: 230A

- Max Rated Stick Amps: @220V: 160A

- MIG Amps/Volts @ Rated Duty Cycle: @220V: 230A/25.5V @ 15% Duty Cycle @ 40°C - @220V: 200A/24V @ 35% Duty Cycle @ 40°C - @220V: 160A/22V @ 60% Duty Cycle @ 40°C

- Stick Amps/Volts @ Rated Duty Cycle: @220V: 160A/26.4V @ 35% Duty Cycle @ 40°C - @ 220V: 130A/25.2V @ 60% Duty Cycle @ 40°C

- Max Inrush (I1MAX) Amps: @ 220V: 40A

- Maximum Rated (I1EFF) Input Amps: @220V: 20A

- OCV: MIG: 60V - Stick: 60V

- MIG Output Range: @ 220V: 30-230A; 15.5V-25.5V

- Stick Output Range: @220V: 10-160A: 20.4V-26.4V

- Variable MIG Inductance/Stick Arc Force Control: Yes

- Spool Gun Capable: Yes

- Pulse: No

- Separate wire feeder: No, self-contained

- Number of Drive rollers: 2

- Max Wire Feed Speed: @240V: 600IPM

- Max Wire Roll Diameter: 8” (up to 12 lb.)

- Memory: No

- Preflow time: 1-10 Seconds, or Auto

- Post Flow Time: 0-10 Seconds, or Auto

- Flux Core: Yes, Optional

- 2T/4T /Torch latch/Trigger: Yes

- Torch Type: MIG: 15 Series

Other Features:

- Standard Drive Roll Size: V groove and Flux Cored .030"-.035" (Others optional)

- MIG Spot Time: 0-15 Seconds

- MIG Stitch Time: 0-15 Seconds

- MIG Burn Back Time: 0-2 Seconds

- Stick Arc Force: 0-100%

- Stick Hot Start Time: 0-2 Seconds

- Stick Hot Start Intensity: 0-100% over set Amperage (based on Amp availability)

Minimum/Maximum:

- Weld up to a maximum of 3/8+" Steel/Stainless single pass weld* 220V

- Weld up to a maximum of 1/2" Steel/Stainless multiple pass weld 220V

- Weld a minimum of 24-gauge Steel/Stainless** 120/220V

- Weld a maximum of 1/8" Steel/Stainless single pass weld 120V

- Weld a maximum of 1/4" Steel/Stainless multi-pass weld 120V

Purchase the SM200N or SM3035N gun to weld Aluminum or purchase a .035"/.045" 1 piece drive roll kit to weld aluminum along with a polymer liner for the standard 10 ft gun.

- Weld up to a maximum of 3/16" Aluminum single pass weld* 220V

- Weld up to a maximum of 3/8" Aluminum multiple pass weld 220V

- Weld a minimum of 14-gauge Aluminum** 120/220V

- Weld up to a maximum of 1/8" Single pass weld 120V

- Weld up to a maximum of 3/16" multi-pass weld 120V

*Single pass welds greater than 1/4" and 3/16" for Steel/Stainless/Aluminum are not generally recommended for this size unit as a sound welding technique with this size machine. These figures are given purely for statement of capability, not of practicality.

** When performed by experienced users. Spray transfer with Aluminum is the correct method of MIG welding aluminum. Short circuit welding of aluminum is not recommended as porous welds and lack of fusion will result.

Stick:

- Weld with a minimum of 1/16" diameter electrode 120/220V

- Weld with a maximum of 1/8-5/32" diameter electrode 220V

- Weld with a maximum of 3/32 diameter electrode 120V

This unit is not recommended for use with E6010.

Maximum electrode diameter is ultimately dependent upon rod type and electrode manufacturer recommendations.

NOTE: If using with a generator, the generator must be rated by its manufacture as clean power. This means that the Total Harmonic Distortion (THD) is 5% or less. Use with generators that are 10,000 Surge Watts or greater. If operating on 120V, use a generator with clean power output and a minimum output of 4500 Surge Watts. When using with a generator, failure to use a clean power generator properly rated for the wattage required will void the generator's warranty.

This unit's maximum output is 230A @ 15% duty cycle, however at 200A the unit's duty cycle increases to 35%.

PLEASE NOTE: To achieve the maximum performance out of your Everlast Machine please ensure your current breaker and wiring/socket setup at your place of use is sufficient enough to achieve this. For example, you may be required to upgrade your breaker to a 32A dedicated circuit to suit, therefore allowing you to achieve your machines full duty cycle. If in doubt, please contact your local licensed electrician for more info prior to purchasing and please see terms and conditions/warranty for more information.

Manufactured and compliant with IEC/AS 60974.10, CE Guaranteeing your electrical safety and performance. INDUSTRIAL USE ONLY